Thomas Edison Directs an Experiment on Insulating Wires, to Make Running Electric Wiring Underground Possible

It was part of his grand vision for centralized electric power, and for selling his electric lamps

“The linseed oil you are using in tubes & on armature paper is very acid. If you take your armature paper & put on tongue, it will taste sour. Better have sent me at once 1 gallon of oil from every dealer & I will test. The armature paper is lower resistance...

“The linseed oil you are using in tubes & on armature paper is very acid. If you take your armature paper & put on tongue, it will taste sour. Better have sent me at once 1 gallon of oil from every dealer & I will test. The armature paper is lower resistance than paper itself. Add 5% paraffin immediately to compound until you can get right oil. Paraffin I find corrects considerably the effects of the acid.”

Edison began manufacturing lamps during the summer of 1880. Originally known as the Edison Lamp Works, the company changed its name to the Edison Lamp Company in 1882. A year later it moved its factory from Menlo Park to East Newark (Harrison), NJ. The company merged with several other Edison companies in 1889 to become the Edison General Electric Company.

To sell lamps and promote electricity, Edison had a vision for centralized power. But to accomplish this, he needed to run electric wiring underground. Unshielded wires would leak electricity and were subject to corrosion and short-circuits. After experimenting with a variety of insulating materials, Edison finally decided on asphalt with beeswax, paraffin, and linseed oil. Armatures were used in electrical installations, so the insulating materials had to be compatible with it.

John Kruesi was a shareholder in the Concentrating Works. He had been apprenticed as a locksmith in Switzerland, and migrated to the United States where he settled in Newark, New Jersey. There he met Thomas Edison, who was impressed with the young Swiss immigrant and took a liking to him, employing him in his workshop starting in 1872. He became Edison’s head machinist through his Newark and Menlo Park periods, responsible for translating Edison’s numerous rough sketches into working devices. Since constructing and testing models was central to Edison’s method of inventing, Kruesi’s skill in doing this was critical to Edison’s success as an inventor. By the late 1880s, Kruesi was General Manager of the Edison Machine Works, a company set up to produce dynamos, large electric motors, and other components of electrical illumination.

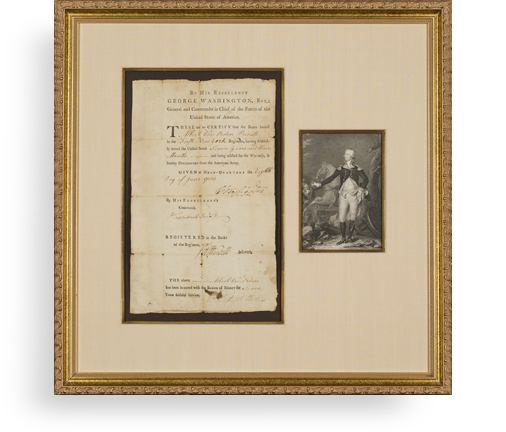

But there was a problem, so Edison wrote Kruesi. Autograph letter signed, on his Edison Lamp Company letterhead, Harrison, NJ, no date but from information on the letterhead and the text between 1883-85, to Kruesi. The letter clearly shows the extent to which Edison sought perfection, and how he went about his experiments. “You are in a pretty scrape. The linseed oil you are using in tubes & on armature paper is very acid. If you take your armature paper & put on tongue, it will taste sour. Better have sent me at once 1 gallon of oil from every dealer & I will test. The armature paper is lower resistance than paper itself. Add 5% paraffin immediately to compound until you can get right oil. Paraffin I find corrects considerably the effects of the acid. This is very serious & show the necessity of having someone up there to test your materials – under any condition. Yours, Edison.”

This fascinating letter is unpublished. We obtained it from the Kruesi descendants, and it has never before been offered for sale.

Frame, Display, Preserve

Each frame is custom constructed, using only proper museum archival materials. This includes:The finest frames, tailored to match the document you have chosen. These can period style, antiqued, gilded, wood, etc. Fabric mats, including silk and satin, as well as museum mat board with hand painted bevels. Attachment of the document to the matting to ensure its protection. This "hinging" is done according to archival standards. Protective "glass," or Tru Vue Optium Acrylic glazing, which is shatter resistant, 99% UV protective, and anti-reflective. You benefit from our decades of experience in designing and creating beautiful, compelling, and protective framed historical documents.

Learn more about our Framing Services