Thomas Edison Specifies the Qualifications He Required of Employees

Writing to his chief assistant, John Kruesi, he says:“Want a man who is not so very refined, a rough and practical young man, salary $18 per week. Kid gloves & cigarettes not permitted.”

Revealing his excitement about his new mining operation, Edison hopes Kruesi soon “will be able to leave the light business and come with Batch and I into the mining business where you may be dirty but very happy.”

One significant interest of Edison’s in the 1890s was an ore-milling process that would...

Revealing his excitement about his new mining operation, Edison hopes Kruesi soon “will be able to leave the light business and come with Batch and I into the mining business where you may be dirty but very happy.”

One significant interest of Edison’s in the 1890s was an ore-milling process that would extract various metals from ore and also address an iron ore shortage. In 1889, he formed the New Jersey and Pennsylvania Concentrating Works, and soon became so absorbed by its operations that he began to spend much time away from home at the mines in Ogdensburg, New Jersey. There he designed rock-crushing technology and an electromagnetic ore separator to extract low-grade ore from crushed boulders. He believed in this project and would invest almost a decade of his life and over two million dollars of his own money in it.

John Kruesi was a shareholder in the Concentrating Works. He had been apprenticed as a locksmith in Switzerland, and migrated to the United States where he settled in Newark, New Jersey. There he met Thomas Edison, who was impressed with the young Swiss immigrant and took a liking to him, employing him in his workshop starting in 1872. He became Edison’s head machinist through his Newark and Menlo Park periods, responsible for translating Edison’s numerous rough sketches into working devices. Since constructing and testing models was central to Edison’s method of inventing, Kruesi’s skill in doing this was critical to Edison’s success as an inventor. By the late 1880s, Kruesi was General Manager of the Edison Machine Works, a company set up to produce dynamos, large electric motors, and other components of electrical illumination. In 1889 the Machine Works business moved to Schenectady, NY. However Kruesi was still assisting Edison in a variety of other projects, and Edison was hoping to get him back from Schenectady to New Jersey where Edison himself was located.

Edison determined that he needed another electrician for the mining operation in which he and Kruesi both had an interest, and he turned to Kruesi for help. Autograph letter signed, on New Jersey and Pennsylvania Concentrating Works letterhead, Ogden, N.J., no date but 1899, to Kruesi. “We are in need of another electrician. Want a man who is not so very refined, a rough and practical young man, salary $18 per week. Kid gloves & cigarettes not permitted. I hope by next year you will be able to leave the light business and come with Batch and I into the mining business where you may be dirty but very happy. Yours, Edison.” The Batch mentioned in the letter is Charles Batchelor, a close Edison associate and inventor. He was general manager of General Electric, a post he left in 1899 to work with Edison in his mining operation, thus dating this letter.

We obtained this letter from the Kruesi descendants, and it has never before been offered for sale.

The final product — a briquette made of powdered iron ore — didn’t do well commercially, especially after high-grade ore was discovered around Lake Superior. In 1899, Edison left the industry.

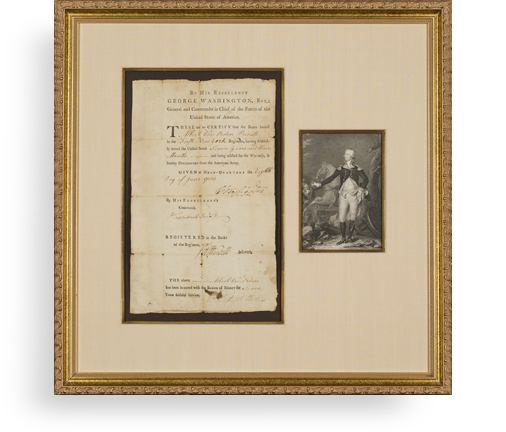

Frame, Display, Preserve

Each frame is custom constructed, using only proper museum archival materials. This includes:The finest frames, tailored to match the document you have chosen. These can period style, antiqued, gilded, wood, etc. Fabric mats, including silk and satin, as well as museum mat board with hand painted bevels. Attachment of the document to the matting to ensure its protection. This "hinging" is done according to archival standards. Protective "glass," or Tru Vue Optium Acrylic glazing, which is shatter resistant, 99% UV protective, and anti-reflective. You benefit from our decades of experience in designing and creating beautiful, compelling, and protective framed historical documents.

Learn more about our Framing Services